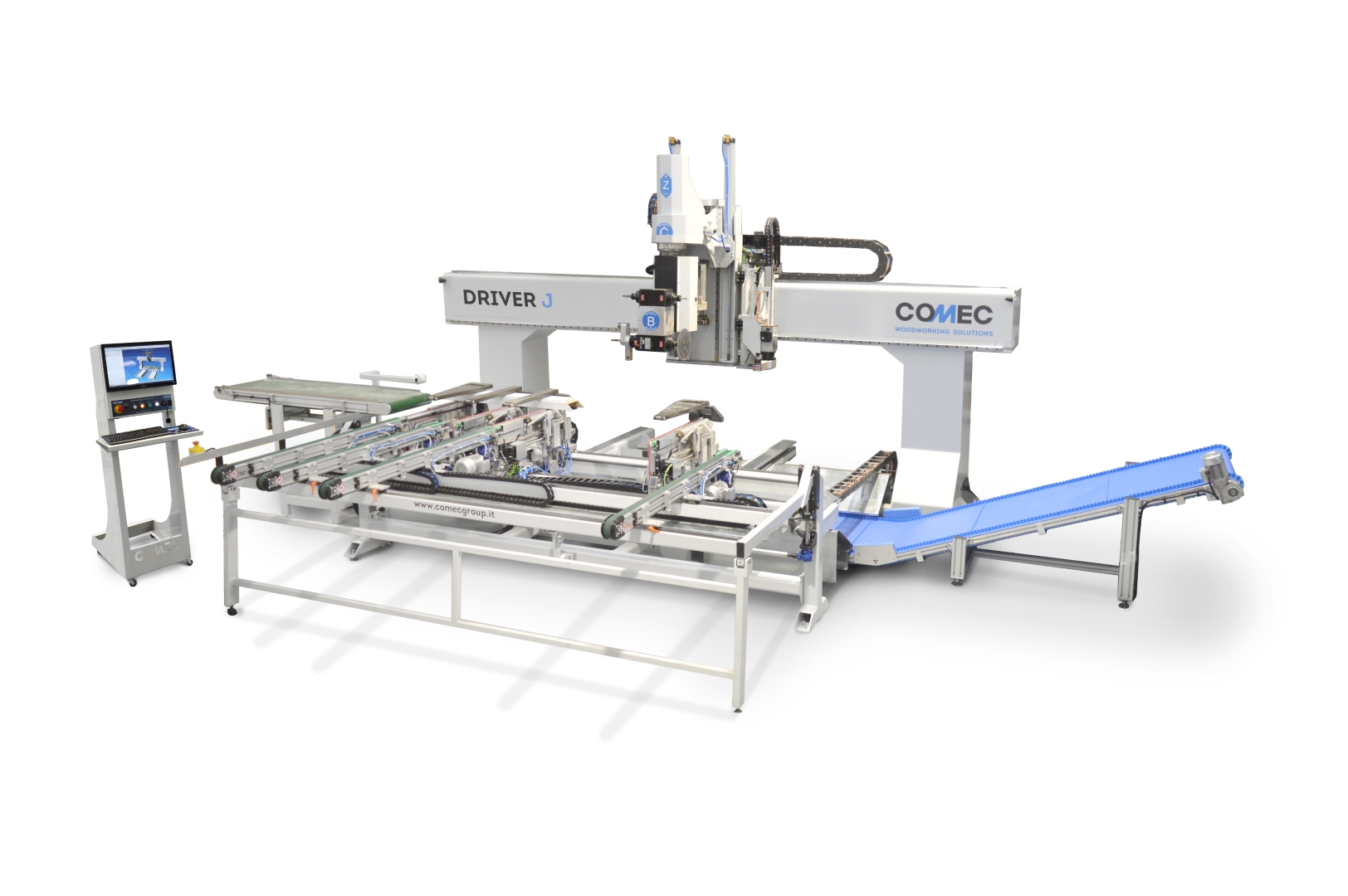

DRIVER 150 L

Description and processes

DRIVER 150 L is the new 5-axis interpolated NC working center with a portal structure to a multi-spindle operating head, mainly dedicated to the machining of wood or wood-derived elements of complex shape.

DRIVER 150 L is the solution designed to perform, in a single positioning, all those 3D machining operations that require absolute precision and accuracy as well as amplitude of movements in space.

ONE MACHINE FOR MULTIPLE APPLICATIONS

Innovative features, among which the remarkable dimensions of the working fields stand out, make the DRIVER 150 L the ideal solution for multiple applications in the wood-furniture sector in both small-medium production realities and large industry.

Strengths

One-piece portal structure, entirely manufactured by the in-house production chain, with quality control on strength, compactness and rigidity, suitable for high-precision machining at high speed.

In automatic mode DRIVER 150 L performs fast, precise and quality machining with guaranteed repeatability over time. The multi-spindle head and easy tooling make the machine extremely flexible and fast, to be used with significantly higher performance than conventional working centers.

DRIVER 150 L has 2 wide and completely independent working fields, in order to allow alternating machining of even elements that differ in shape and size. The 2 fields can work together simultaneously in the case of parts with lengths exceeding that allowed by each individual field.

Each field is equipped with workpiece locking benches with pneumatic cylinders or powerful vacuum system.

The large working space is still compact and optimized and the environment is clean, thanks to the chip and scrap collection and evacuation system with conveyor belt, located at the base of the machine.

All this is assisted by powerful 3D programming software that can also integrate collision control and trajectory optimization.

Advantages

- – Greatest production flexibility- High productivity

– One machine for multiple applications

– Larger working fields than similar models on the market

– Highest quality mechanics resulting from in-house production chain

– Efficient cleaning thanks to dust collection and waste unloading system

– Simple and intuitive programming with dedicated software

– Wide customization

– Proven technology for industrial use, even on multiple shifts

Request

information

Contact us for any information, clarification and specification on our products and services.

T. +39 0432 756282

info@comecgroup.it