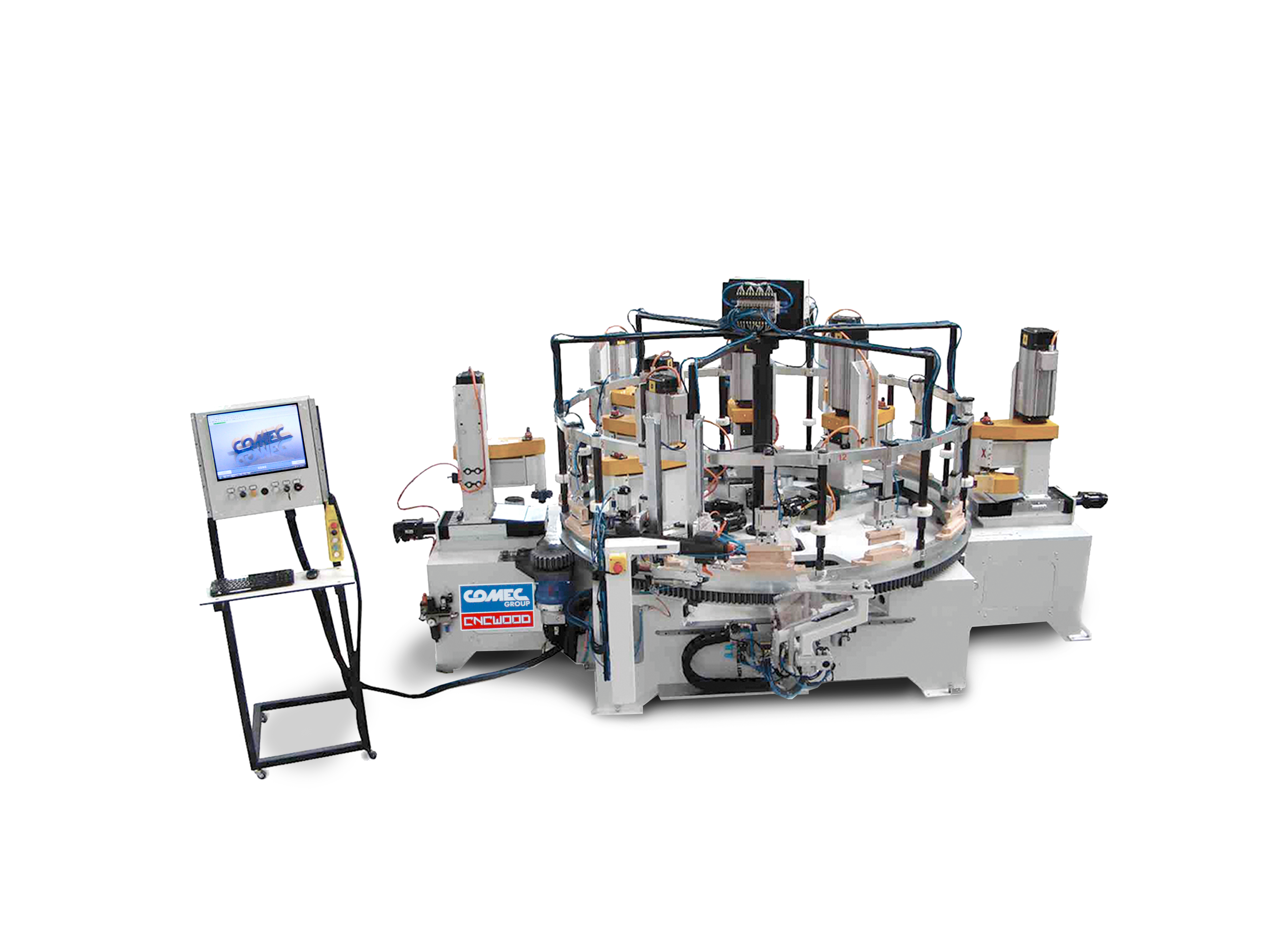

FGR 8T CN CA

Description and processes

NC MILLING/SANDING WORKING CENTER with 9 interpolated axes with eight operating heads and 8-seater rotating table, equipped with automatic workpiece loader and unloader.

FGR 8T CN+CA is the ideal solution for contouring/profiling and sanding operations to be carried out simultaneously on the internal and external side of long shaped elements, large and small, up to 1000mm long, in a single positioning. It finds its optimal use in the processing of chair legs and backrests, table legs, bed heads, sofa elements, brush handles or furnishing accessories.

Strengths

The innovative construction geometry makes the machine particularly compact and robust, for high speed machining, even in the presence of heavy duty machining. FGR 8T CN+CA automatically performs fast, precise and high quality processings with a guarantee of repeatability over time. The four + four independent heads allow the machine an extreme flexibility of use, without the use of copy templates.

The workbenches guarantee the clamping of the elements in a safe and precise way, in an optimized space and in a clean working environment thanks to the soundproof cabin that surrounds the whole machine. The ergonomic and capable automatic loading makes the operator’s work easier and is also suitable for robotic applications.

Easy programming thanks to the touch-screen NC panel.

Advantages

- High productivity

- No copying template

- 3 Independent working units (no tool change required)

- Robust, high quality mechanics

- Efficient cleaning with dust collection and extraction

- Simple and intuitive programming with dedicated software

- Wide customization

- Proven technology for industrial use, even over several shifts

Request

information

Contact us for any information, clarification and specification on our products and services.

T. +39 0432 756282

info@comecgroup.it