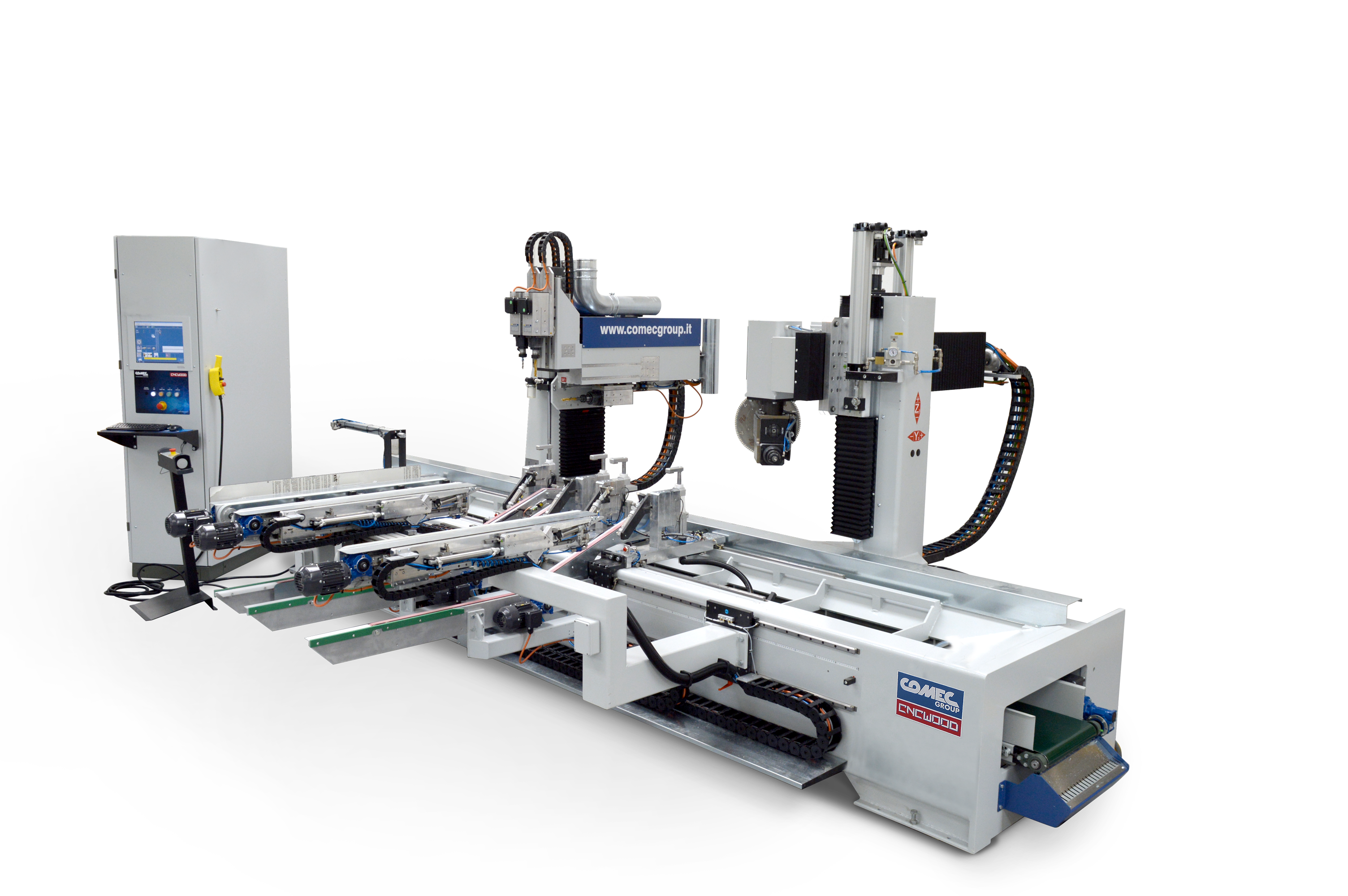

MD FAST 2T CA3

Description and processes

7-axis NC WORKING CENTER with two independent multi-spindle operating heads, with horizontal automatic loader.

MD FAST 2T CA3 is the ideal solution for cutting, milling or drilling operations on long shaped elements up to 2700mm in a single positioning. It finds its main application in the processing of elements for internal doors, doors and windows, wooden stairs, urban furniture.

Strengths

The ideal machine for small to medium productions, where flexibility is important. Automatically, MD FAST 2T CA3 performs fast, precise and quality processings with a guarantee of repeatability over time. The two multi-spindle heads with independent machining allow the machine extreme flexibility of use with significantly higher performances compared to conventional working centers.

The special motorized workbenches guarantee the clamping of elements in an automatic and precise way, repositioning automatically even during operations. The special horizontal automatic loader facilitates the operator’s activity in loading even heavy and particularly shaped pieces. This loading system is particularly suitable in case of robot-mediated loading. Easy programming thanks to the NC touch screen panel.

Advantages

- High “just in time” productivity and multitasking working operations.

- 2 Multi-spindle working units (no tool change required)

- Automatic set-ups

- High quality mechanics

- Efficient cleaning with dust collection, extraction and waste disposal

- Simple and intuitive programming with dedicated software

- Wide customization

- Proven technology for industrial use, even over several shifts

- Possibility to be inserted in automatic production lines

Request

information

Contact us for any information, clarification and specification on our products and services.

T. +39 0432 756282

info@comecgroup.it