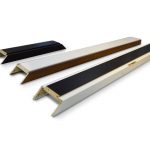

MD JAMB 11X CA3L

Description and processes

11-axis NC WORKING CENTER with three independent multi-spindle operating heads, with automatic loader.

MD JAMB 11X is the ideal solution for cutting, milling or drilling operations on all faces of long shaped elements up to 3200 mm in a single positioning and finds its optimal use in the processing of door jambs, flat or assembled.

Strengths

“The door jamb Machine”

“Just-in-time” production even in batch one, thanks to the possibility to load in sequence the elements of a single door.

Automatically, MD JAMB 11X CA3L performs fast, precise and quality processing with a guarantee of repeatability over time. The three multi-spindle heads with independent machining allow the machine an extreme flexibility of use with much higher performances compared to conventional working centers.

The special workbenches guarantee the automatic and precise clamping of complex elements. All this is supported by powerful parametric 3D programming software with advanced data management functions.

Advantages

- One machine for every jamb design

- High productivity and multitasking operations

- 3 Multi-spindle working units (no tool change required)

- Fully automatic set-up

- High quality mechanics

- Efficient cleaning with dust collection, extraction and waste disposal

- Simple and intuitive programming with dedicated software

- Wide customization

- Proven technology for industrial use, even over several shifts

- Possibility to be inserted in automatic production lines

Request

information

Contact us for any information, clarification and specification on our products and services.

T. +39 0432 756282

info@comecgroup.it