FRONTAL CN 3S 2000

Description and processes

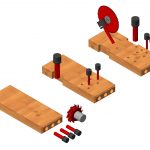

NC MULTI-PROCESS WORKING CENTER with 3 working stations, 6 multi-spindle operating units, automatic loader and workpiece return system to the operator.

FRONTAL CN 3S 2000 is the ideal solution for cutting, milling, multiple drilling on long shaped elements up to 2000mm length, on multiple stations, in a single positioning. It finds its optimal use in the machining of furniture and bed elements, such as legs and frames. Particularly recommended in the production of furniture elements in kit form.

Strengths

High productivity thanks to the automatic positioning on multiple stations where all the operating heads work simultaneously, combined with the flexibility typical of NC machining. Automatically, FRONTAL CN 3S 2000 performs fast, precise and quality machining with guaranteed repeatability over time.

The special system of loading, station feed and synchronized clamping of the parts guarantees precise and clean processing even on surfaces with delicate finish.

Advantages

- High productivity

- Multi-spindle point-to-point working unit

- Fast and precise set-ups, also automatic

- One operator per loading/unloading

- High quality mechanics

- Efficient cleaning with dust collection, extraction and waste disposal

- Simplified programming with dedicated software

- Wide customization

- Proven technology for industrial use, even over several shifts

Request

information

Contact us for any information, clarification and specification on our products and services.

T. +39 0432 756282

info@comecgroup.it